Do you want the same pumps like them?

Constant Displacement

Application:Mobile Machinery

Service life: 20,000 hours

Variable Displacement

Application:Industrial Equipment

Service life: 20,000 hours

Variable Displacement

Application:Mobile Machinery

Service life: 20,000 hours

Variable Displacement

Application:Industrial Equipment

Service life: 20,000 hours

Bohang hydraulic piston pump running long time without failures at Customer’s site

| Model | Have been used | Application | Operation |

| A2F80R2P3 | 2 years and 11 months | Cleaning Equipment | More |

| A2FE160/61W-VZL181 | 3 years and 11 months | Hydraulic Impactor | More |

| A7V107LV2.0LZF00 | 3 years and 2 months | Static pressure pile extractor | More |

| A7V160EP2.0LPF000 | 3 years and 7 months | Metal forming machine | More |

| A2F016/61L-VAB06 | 3 years and 9 months | Pumper | More |

| A2F80R2P3 | 2 years and 11 months | Hydraulic Impactor | More |

| A7V160EP2.0LPF00 | 3 years and 8 months | Cleaning Equipment | More |

| A6V160HA22FZ2 | 2 years and 11 months | Metal forming machine | More |

| A2F80R2P3 | 2 years and 11 months | Cleaning Equipment | More |

| A2FE160/61W-VZL181 | 3 years and 11 months | Hydraulic Impactor | More |

| A7V107LV2.0LZF00 | 3 years and 2 months | Static pressure pile extractor | More |

| A7V160EP2.0LPF000 | 3 years and 7 months | Metal forming machine | More |

| A2F016/61L-VAB06 | 3 years and 9 months | Pumper | More |

| A2F80R2P3 | 2 years and 11 months | Hydraulic Impactor | More |

| A7V160EP2.0LPF00 | 3 years and 8 months | Cleaning Equipment | More |

| A6V160HA22FZ2 | 2 years and 11 months | Metal forming machine | More |

How to Diagnose your hydraulic pump?

-

Problem1

No flow output from pump

Analysis

1. Pump not rotates?

2. Pump turns reversely?

3. Pump Axial can still rotate?

4. Pump not drafts in fluid?

Contact for solution -

Problem

Loud noise

Analysis

1.Not drafts in fluid at all?

2.Drafts in bubble?

3.Hydraulic pump runs NG?

4.Hydraulic pump structure fault?

5.Hydraulic pump not be installed well?

Contact for solution -

Problem

Output fluid not enough?

Analysis

1.Low volume efficiency?

2.Pump drafts in air?

3.Inner structure works failure?

4.Not enough fluid supply?

Contact for solution -

Problem

Weak pressure?

Analysis

1. Leakage seriously?

2.Low power for drive module?

3.Too heavy Pump flow or too high pressure?

Contact for solution -

Problem

Unstable Pressure and flow?

Analysis

1. Pump drafts in air?

2.Fluid too dirty?

3.Assembly fault?

4.Hydraulic pump structure fault?

5.Fluid supply unstable?

Contact for solution -

Problem

Abnormal Heat?

Analysis

1.Assembly fault?

2.Poor fluid quality?

3.Pipeline failure?

4.Ambient environment reason?

5.Heavy inner leakage, low volume efficiency causes abnormal heat?

Contact for solution -

Problem

Leakage from axial sealing?

Analysis

1.Installation failure?

2.Poor processing quality for axial and grooves?

3.Fluid sealing failure?

4.Low volume efficiency?

5.Oil drain port is blocked off?

6.External oil drain pipe is too thin or too long?

7.No connects the oil drain pipe?

Contact for solution

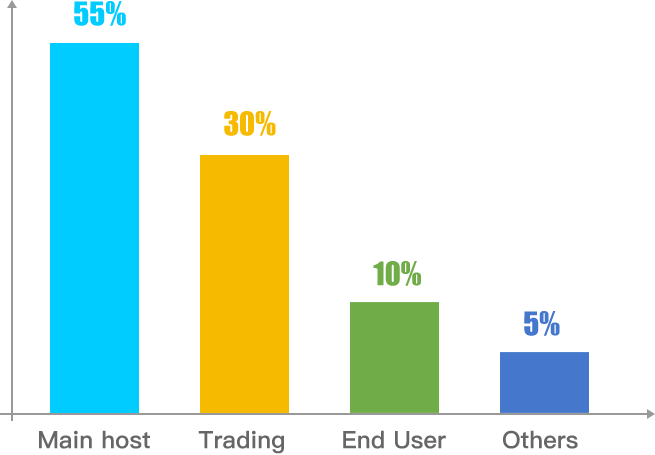

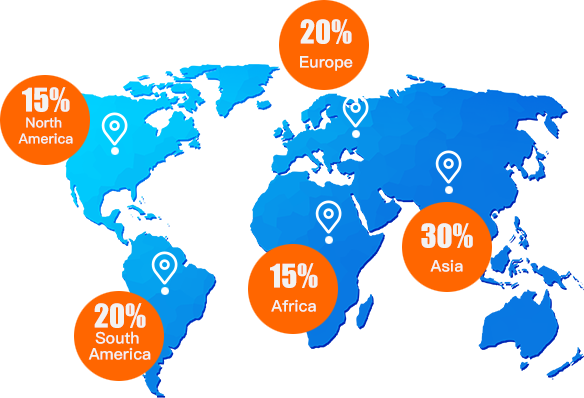

Why choose Bohang Hydraulics?

Already service 26,000 customers

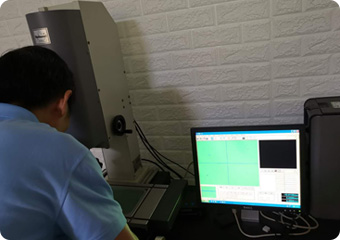

Manufacturing Process

-

Processing

-

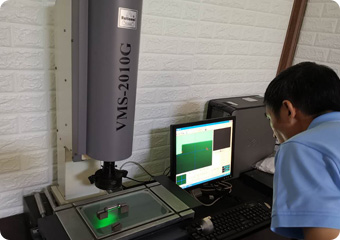

Measure

-

Assembly

-

Test

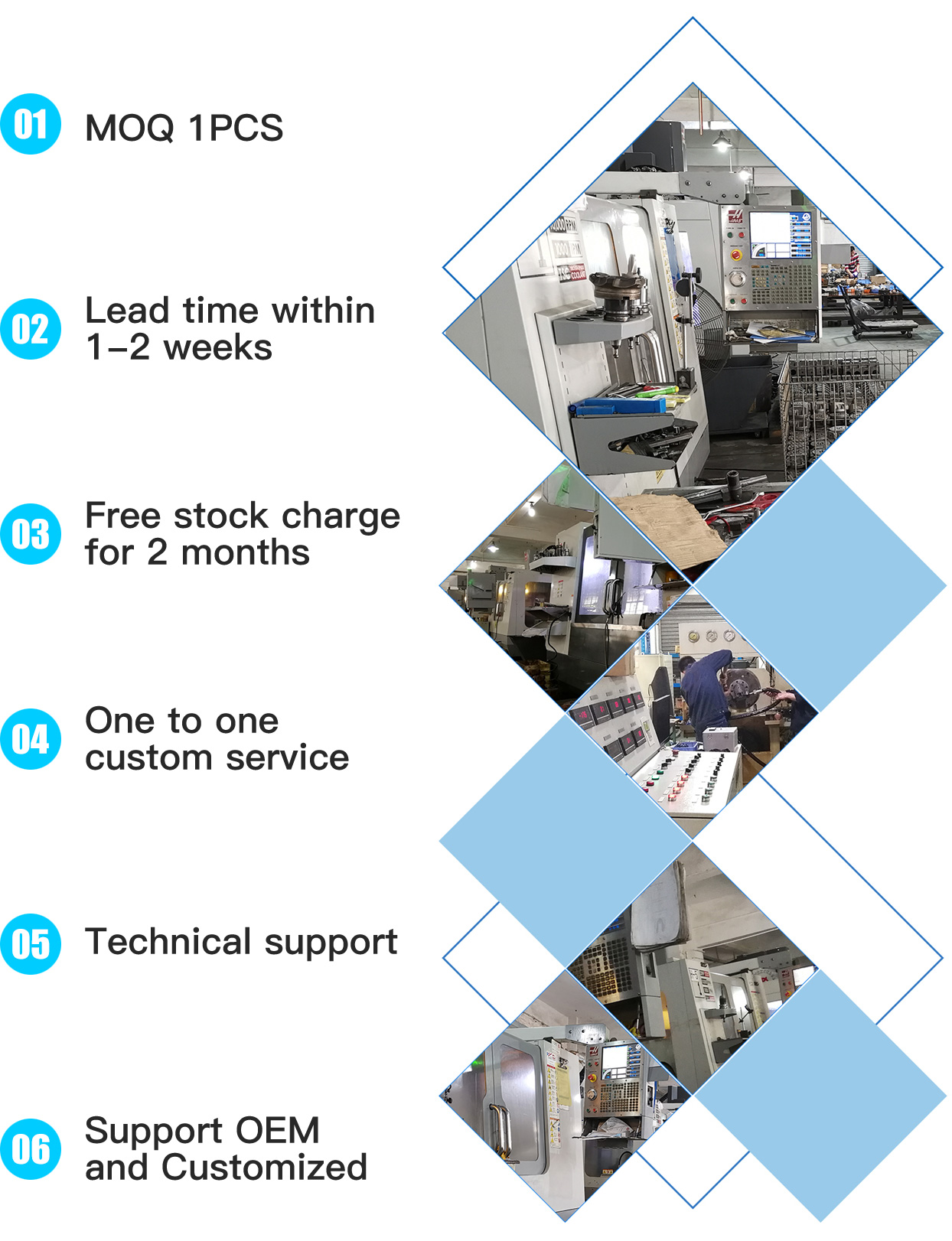

What we bring to you?

-

Technical Guarantee

13-year brand, Military Quality

-

Quality Guarantee

High efficiency, Pressure resistance, Long running time

-

After-sales Guarantee

Worry-free quality guarantee, one to one on time customer service

-

Short lead time

1-2 week lead time

Get Your Free Quote for Hydraulic Solutions Now

Leave your contact information and our sales team will get back to you within 24 hours.